FULL AUTOMATIC SUGAR CUBE MACHINE WITH DRYING OVEN 12 TONS / DAY – Product Code:RGD312

FULL AUTOMATIC SUGAR CUBE MACHINE WITH DRYING OVEN 12 TONS / DAY – Product Code:RGD312

Ürün Açıklaması

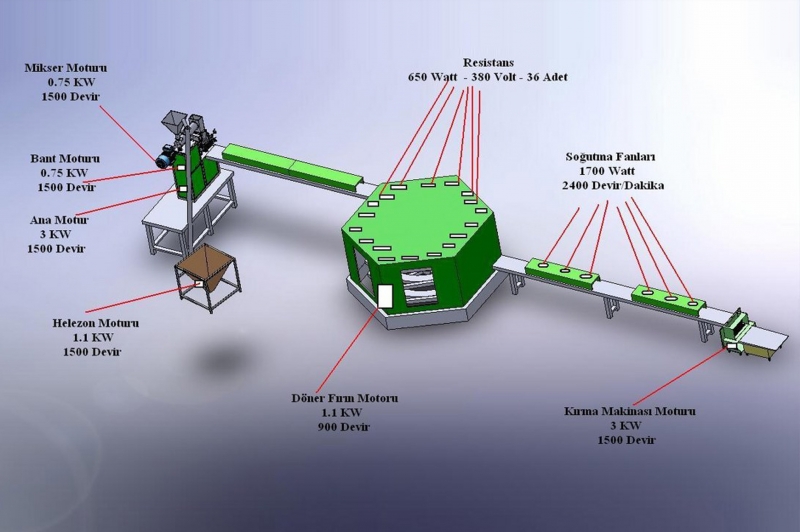

Gold Paketleme Makina Gıda San. ve Dış Tic. A.Ş. is producing the RGD 312 full automatic sugar cube machine which has a capacity of 12 tons / day with the automatic spiral system over 10 years experience. It is equipped with drying oven which makes feeding with the automatic spiral system. The crystal granulated sugar, which comes to the silo section by means of the spiral, is moistened and transferred to the barbotin section with the help of dosing pump. The basis weight settings can be configured according to the preferred sizes and needs of consumers.

The sugar cubes which get out from pressing section, are transferred on the chrome-nickel matting band and the sugar cubes turn around belt pulleys 6 times, which have a diameter of 2000 mm , then the drying process starts. During the drying process, infrared resistances and hot air blowing system are used. The moisture, which occurs in the closed drying oven, is thrown out by the hot air blowing system. This process provides the sugar cubes to be harder and drier. The hard and dry sugars, which get out of drying oven , become sugar cubes by passing from the cooling fans.

The ideal sugar cubes are ranged by means of the filling robot according to the dimensions of the box and filled in the ready-made boxes, which come from the packing box in 2-3-4 serials and vacuumed with the system which provides negative pressure. Then the completely filled boxes are sent to the box-closing machine. The graphically designed boxes, which get out from the press with the requested dimensions, are placed into the magazine section of the box making machine as 500 or 1000 pcs. They are taken by the greasy vacuum and pasted from 4 sides and they turn into boxes, then these boxes are left on the conveyor band in order, to go to the filling robot. According to the consumer’s request, automatic packing system can be added to the output of the box-closing machine.