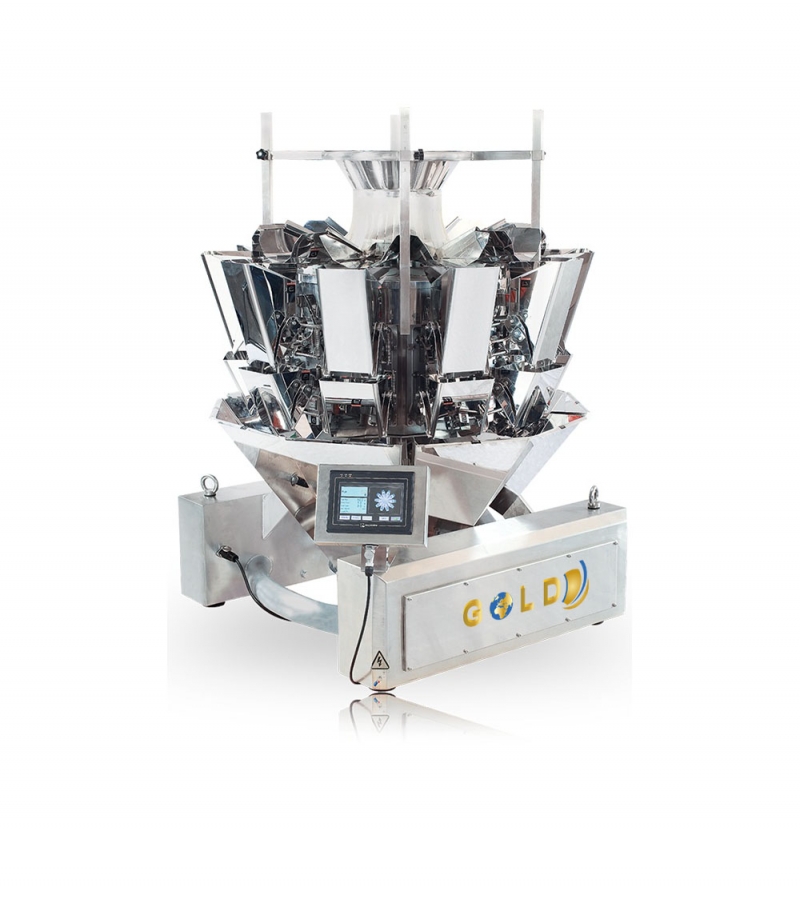

GOLD 1000 – MULTI SCALE VERTICAL PACKAGING MACHINE

GOLD 1000 – MULTI SCALE VERTICAL PACKAGING MACHINE

Ürün Açıklaması

Gold Paketleme Makine Gıda San. ve Dış Tic A.Ş is producing the Gold 1000 – Multi Scales Vertical Packaging Machine over 10 years of experience. It is packaging the free-fluent goods, which are granule and powdery crystalised, in a fully automated way. It’s a machine for packing the goods like potato chips, dried fruits, candies etc. in high capacity. Multi-pan scale groups work with the combination method. They base on the indicated combination number without supervising an order between the pans, find the best basis weight in 10 pans ,collects and then relieves to the packing machine. The scales start to work in these periods and the product which was relieved into the packing machine, is pasted by the vertical jaw (claw) according to the pack’s sealing which comes from the collar section in the form of A+A or A+B. The bottom jaw group pulls the pack size as well as the photocell points based/found on the pack, pastes the top section. Optionally, it makes the pack types like flow pack, flat bottom bag, stabilo bag. The flat bottom bag and its handle side can be added to the bottom jaw group in high basis-weight packs optionally. Also, hot and cold jaw sealing process can be used for the pack alternatives which have several specifications.